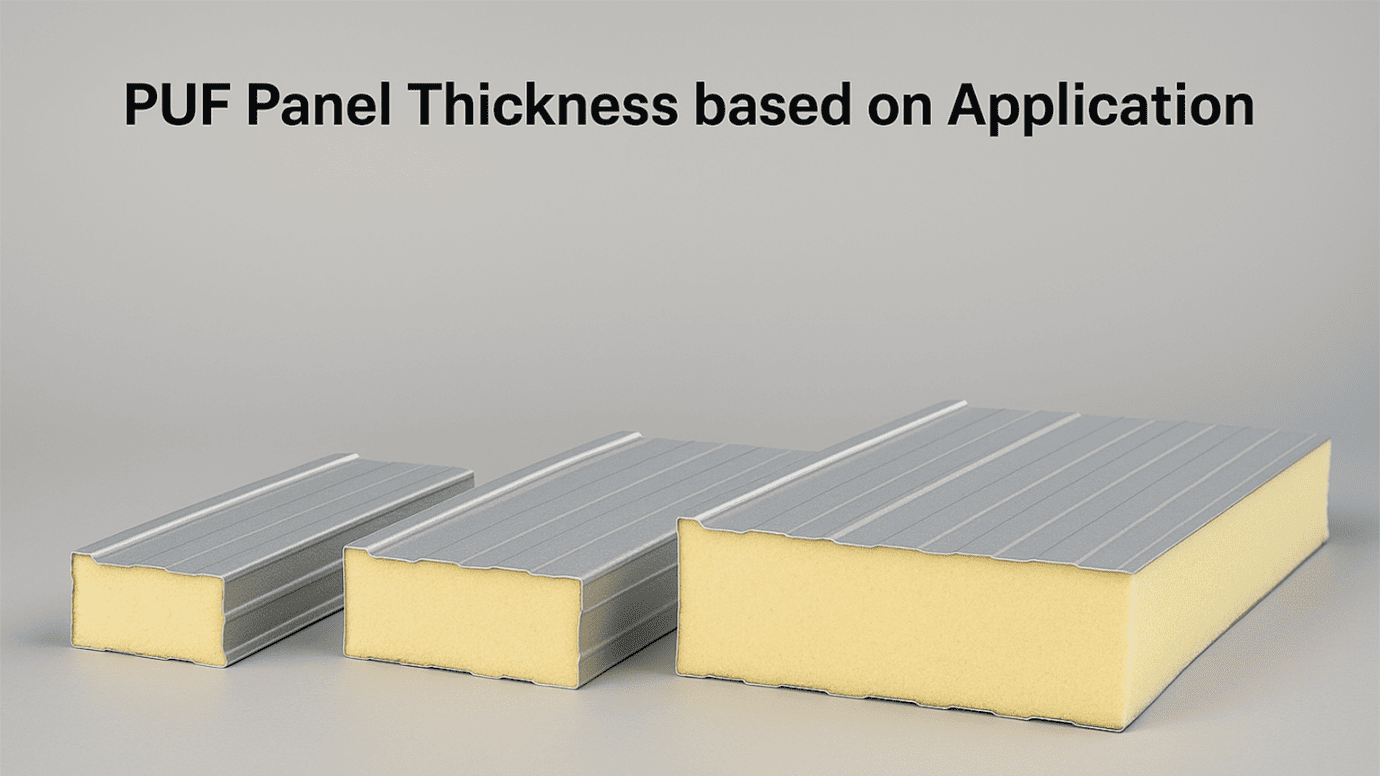

PUF Panel Thickness based on Application

Polyurethane Foam (PUF) panels are at the forefront of modern building technology, offering superior insulation and structural qualities that make them indispensable in various construction and refrigeration applications. Typically crafted from a core of rigid polyurethane foam, these panels are known for their excellent thermal resistance and strength-to-weight ratio. The versatility of PUF panels allows them to serve various crucial roles, from enhancing energy efficiency in buildings to maintaining necessary conditions in cold storage facilities.

The selection of the correct PUF panel thickness is not merely a technical detail; it is a critical decision that impacts energy conservation, cost-efficiency, and overall building performance. Whether it’s determining the cold room panel thickness for preserving perishables or choosing the appropriate roof panel thickness for climatic protection, the right thickness ensures optimal insulation properties and structural integrity.

This blog will assist you through the significance of PUF panel thickness for different applications. We will look into how specific thicknesses meet diverse needs—from the wall panel thickness in mm required for residential buildings to the robust specifications demanded by industrial facilities. Join us as we explore:

- The basic properties and benefits of PUF panels.

- Key factors that dictate the choice of panel thickness.

- Application-specific guidelines for selecting PUF panel thickness.

- Practical advice for the installation and maintenance of these panels.

Understanding the details of PUF panel thickness can lead to substantial benefits, including enhanced energy savings, improved comfort, and compliance with building standards, making it essential for constructors, architects, and property owners alike.

Understanding PUF Panels

Polyurethane Foam (PUF) panels are advanced construction elements designed to give superior insulation and structural support in a variety of building environments. Composed primarily of polyurethane foam, these panels are encapsulated between layers of structural materials like aluminum, steel sheets, or fiberboards. The core material—polyurethane foam—is renowned for its exceptional thermal insulation capabilities, which stem from its low thermal conductivity. This characteristic is crucial in minimizing heat transfer, making PUF panels highly effective in energy conservation and efficiency.

The insulation properties of PUF panels significantly enhance a building’s energy efficiency. By maintaining more consistent internal temperatures, these panels reduce the need for over heating or cooling, thereby lowering energy costs and improving the comfort of indoor environments. The efficiency of insulation is often quantified by the panel’s R-value, which measures thermal resistance. The PUF panel thickness plays a pivotal role in this regard; the thicker the panel, the higher the R-value and the better the insulative performance.

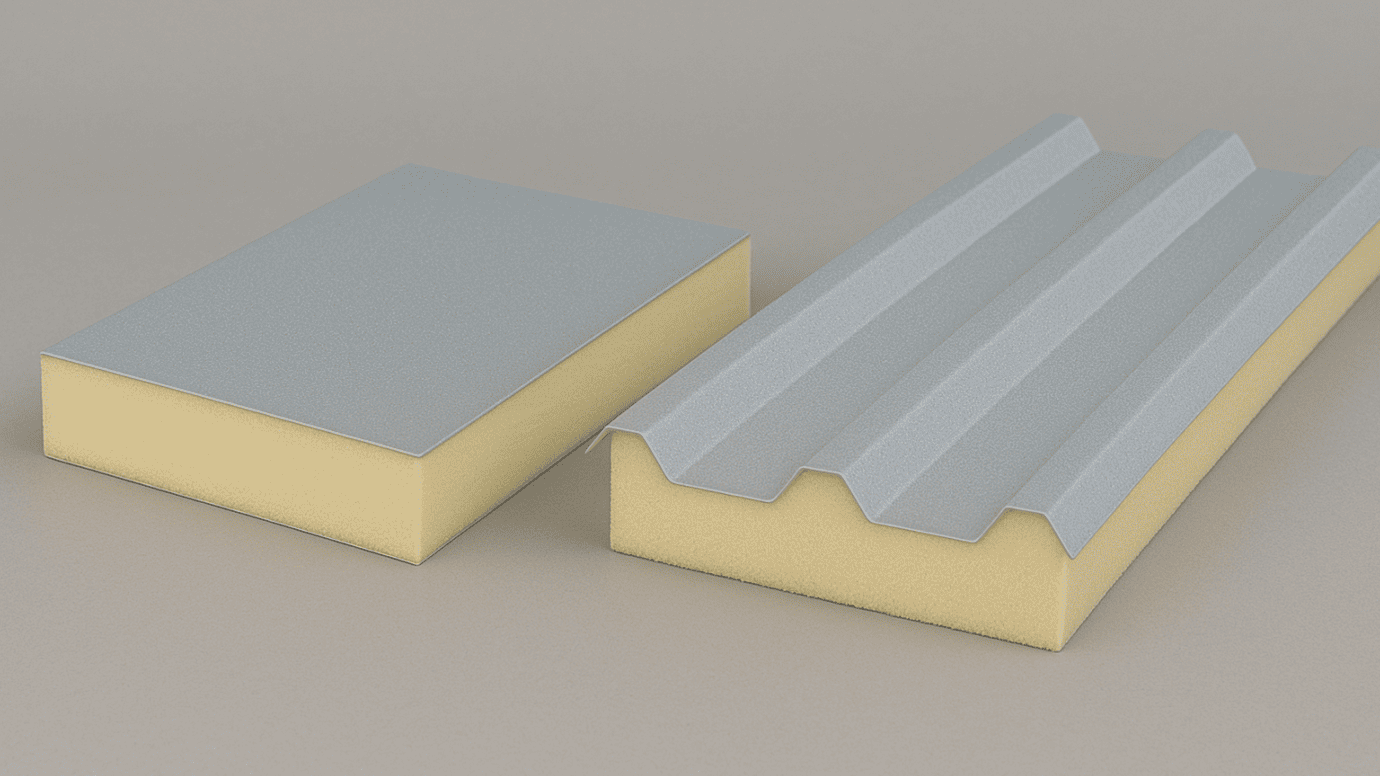

PUF panels are categorized based on their application within the structure, such as wall panels, roof panels, and floor panels:

Wall panels

These are used predominantly in the construction of exterior and interior walls. The wall panel thickness in mm is chosen based on the specific thermal and structural requirements of the building.

Roof panels

These panels are created to provide roofing solutions that offer thermal insulation and water resistance. The roof panel thickness is critical in environments that experience extreme weather conditions, as it must provide both insulation and structural support.

Floor panels

Used primarily in creating insulated flooring, these panels can be crucial in applications like cold storage rooms, where maintaining a constant temperature is vital. The cold room panel thickness is selected to prevent heat gain from the ground and maintain consistent internal temperatures.

Common materials used in conjunction with PUF to enhance its properties include:

Metal sheets

Typically aluminum or steel, these sheets provide a durable exterior that supports the structural integrity and weather resistance of the panel.

Fiberboards

These are often used for interior surfaces where aesthetics are more important but still require a degree of durability and thermal insulation.

Plastic Layers

These can be used for additional moisture resistance and to create a vapor barrier, enhancing the overall effectiveness of the insulation.

Understanding the various types and compositions of PUF panels is essential for architects, builders, and engineers to increase the energy efficiency and durability of their projects. Selecting the right panel thickness and material composition ensures that each application is adequately supported and meets the specific requirements of the environment in which it is used.

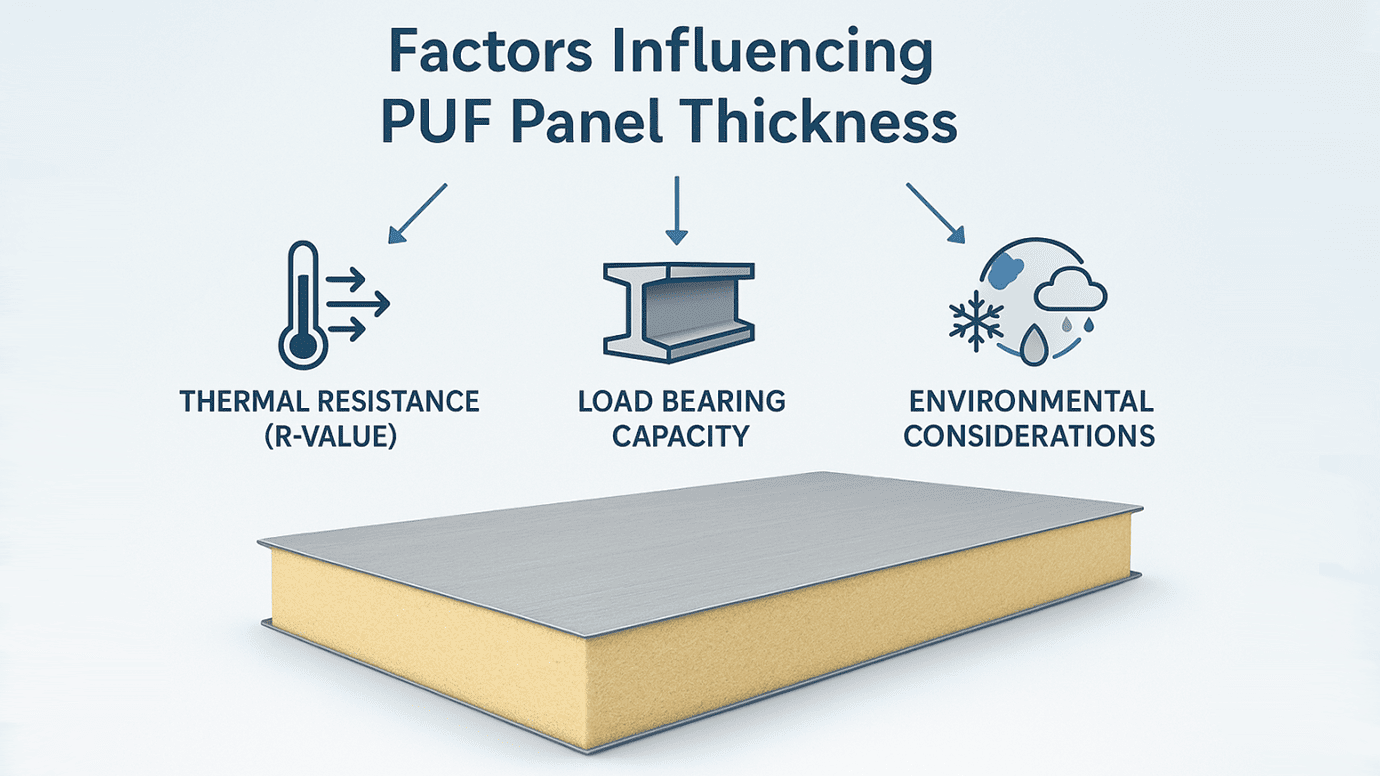

Factors Influencing PUF Panel Thickness

Selecting the appropriate PUF panel thickness is crucial for achieving optimal performance in insulation and structural integrity across various applications. This selection is influenced by several key factors, including thermal resistance, load-bearing capacity, and environmental considerations.

Thermal Resistance (R-Value)

The R-value is a measure of thermal resistance used in the building and construction industry. It quantifies the ability of an insulation material to resist heat flow; the higher the R-value, the greater the insulation power. In the context of PUF panels, the panel thickness directly influences this value. A thicker panel typically has a higher R-value, which means it provides better insulation by slowing the rate at which heat escapes in cold conditions and enters in hot conditions. This makes PUF panel thickness a critical factor in energy-efficient building design, especially for roof panel thickness and wall panel thickness in mm, where effective thermal insulation is vital for maintaining comfortable indoor environments and minimizing heating and cooling costs.

Load Bearing Capacity

The load-bearing capacity of a PUF panel refers to its ability to support weight and withstand external or internal forces without deformation or failure. The structural integrity of these panels increases with greater panel thickness. In structures where panels serve a dual function—both as insulation and as a primary component bearing loads, such as in floors or roofs in industrial buildings—choosing the right PUF panel thickness is essential for safety and durability. For instance, a roof panel thickness must be sufficient to handle not just the typical environmental loads like snow and wind, but also any maintenance activities that might take place on top of the panel.

Environmental Considerations

Environmental factors play a major role in determining the appropriate PUF panel thickness. In colder regions, for example, a greater panel thickness may be required to achieve a higher R-value, which helps in maintaining warmth within the building and reduces heating requirements. Conversely, in warmer climates, sufficient thickness is necessary to keep out the heat and reduce cooling costs.

Furthermore, environmental regulations and standards often dictate specific requirements for insulation materials, including minimum R-values for different parts of a building. Compliance with these standards not only supports energy conservation initiatives but also ensures that buildings are suitable for their environmental context. For instance, the cold room panel thickness needs to be compliant with industry standards to effectively maintain required temperatures for food storage or pharmaceuticals.

Understanding these factors when selecting PUF panel thickness can help in tailoring building designs that are not only efficient and safe but also environmentally responsive and compliant with regulatory standards. Each application, whether it be a residential home, a commercial complex, or an industrial facility, requires careful consideration of these factors to optimize the performance and durability of the PUF panels used.

Recommended PUF Panel Thickness for Various Applications

Choosing the right PUF panel thickness is crucial for meeting the specific needs of different building types and environments. Below, we explore optimal thicknesses for residential, commercial, industrial, and specialized applications, ensuring each choice supports the structure’s functionality and energy efficiency.

Residential Buildings

For residential buildings, the PUF panel thickness plays a vital role in insulation and energy savings. Optimal thicknesses are typically as follows:

1. Walls: A wall panel thickness of 50-100 mm is recommended to provide adequate thermal resistance while keeping construction costs manageable.

2. Roofs: The roof panel thickness should be around 100-150 mm to effectively prevent heat loss, particularly in colder climates.

3. Floors: Depending on the ground temperature and moisture levels, a floor panel thickness of 100-150 mm is ideal to maintain a comfortable indoor environment.

Commercial Facilities

Commercial buildings, including offices, retail spaces, and educational institutions, require varied panel thicknesses based on size and usage:

1. Small commercial buildings often find that a wall panel thickness of around 75 mm and a roof panel thickness of 100 mm are sufficient.

2. Large commercial buildings might opt for up to 150 mm in wall and roof panels to handle greater HVAC loads and larger open spaces.

3. Special considerations for warehouses or cold storages include choosing a cold room panel thickness of at least 150 mm to ensure efficient temperature control crucial for product preservation.

Industrial Applications

Industrial environments, particularly those facing extreme temperatures or chemical exposures, demand robust insulation solutions:

1. Facilities like chemical plants or refineries might need PUF panel thicknesses upwards of 200 mm depending on the specific resistance required against harsh conditions.

2. Example: In a metal fabrication plant exposed to high temperatures, 200 mm thick PUF panels were used for walls and roofs, significantly reducing the energy needed for cooling.

Specialized Applications

For specialized environments such as refrigeration units or soundproofing applications, PUF panel thickness must be carefully selected:

1. Refrigeration units typically require cold room panel thickness between 150-200 mm to maintain the necessary low temperatures efficiently.

2. For soundproofing, panels ranging from 100-150 mm are used depending on the level of noise reduction required.

Each application scenario demands specific considerations regarding PUF panel thickness to ensure optimal performance. Whether enhancing residential comfort, ensuring commercial efficiency, protecting industrial assets, or meeting specialized needs, the correct panel thickness is a critical factor in achieving desired outcomes and ensuring long-term sustainability and cost-effectiveness.

Installation Tips and Best Practices for PUF Panels

Installing PUF panels effectively is crucial to maximizing their performance and longevity. Proper preparation, handling, and installation techniques are essential, especially considering the PUF panel thickness and specific application. This section provides detailed guidance to ensure that these panels are installed correctly, enhancing their insulative properties and structural integrity.

Preparation and Handling

Preparation:

- Site Preparation: Before the installation of PUF panels, ensure that the site is clear of debris and moisture. The surfaces where panels will be installed should be flat and structurally sound to support the panel thickness and weight.

- Measurement and Planning: Accurately measure the area where the panels will be installed. Planning should consider the PUF panel thickness—whether it's the typical cold room panel thickness of 150 mm or a roof panel thickness of 100 mm—ensuring that all panels fit precisely without excessive cutting or resizing.

Handling:

- Transportation: Handle PUF panels with care during transportation. Use protective coverings to prevent surface damage and avoid exposure to moisture.

- Storage: Store panels in a flat position away from direct sunlight and moisture. Ensure that the edges, particularly those of wall panel, are supported to avoid bending.

- Lifting and Moving: Always lift PUF panels using appropriate equipment or sufficient manpower to avoid stressing the panels. Avoid dragging the panels to prevent surface abrasions.

Installation Techniques

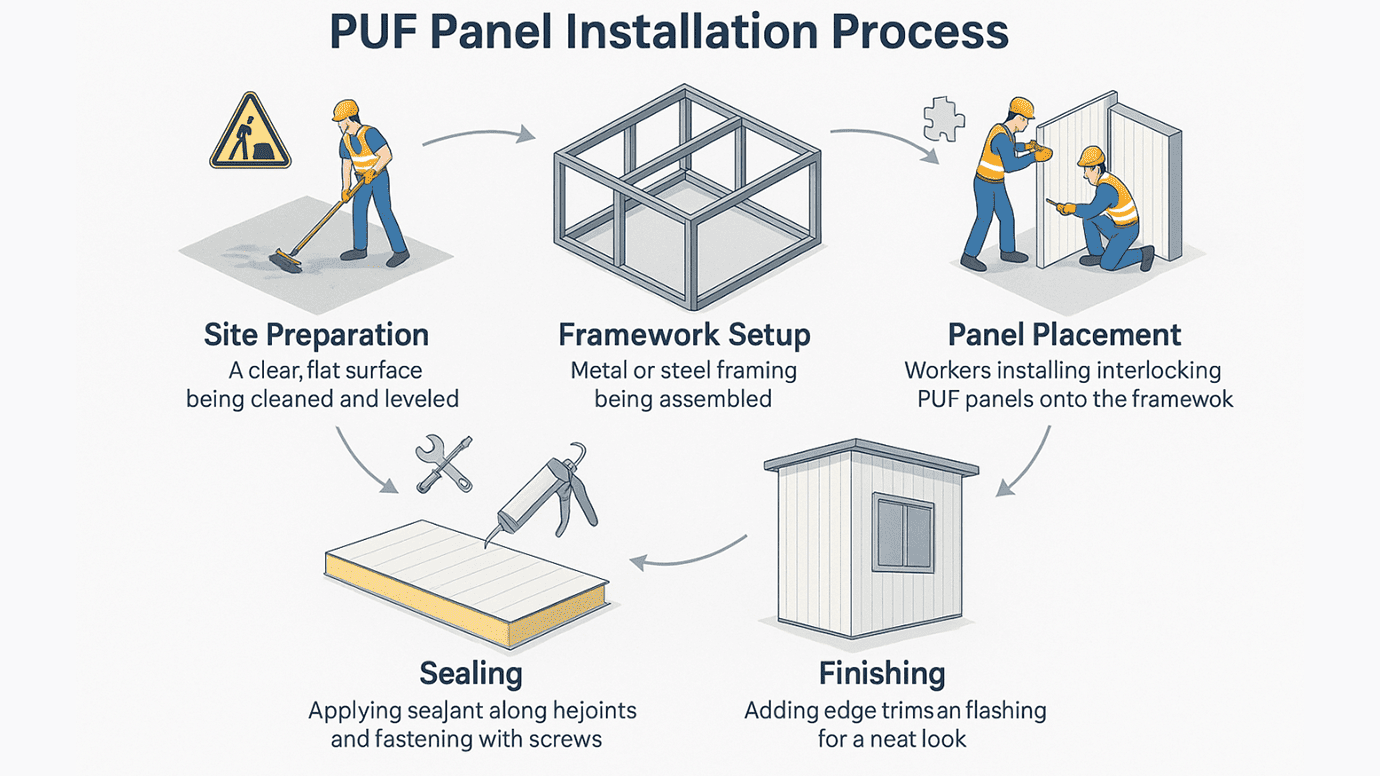

Step-by-Step Guide:

- Framework Setup: Construct a sturdy framework that can support the PUF panel thickness. For larger panels, such as those used in commercial and industrial applications, reinforce the framework to handle additional weight and stress.

- Panel Placement: Begin by placing a corner panel and work your way along the wall or roof. Make sure that each panel is aligned correctly and that the joints are tight to prevent thermal bridges.

- Sealing: Seal all joints with appropriate sealants and use mechanical fasteners to secure the panels to the framework. This is particularly important for cold room panel thickness panels to ensure an airtight environment.

- Finishing: Apply finishing materials such as trim or flashing at the panel edges to protect against environmental factors and to ensure a clean aesthetic finish.

Key Considerations:

- Thermal Bridging: Avoid thermal bridging by ensuring that there are no gaps at the joints. Use continuous insulation techniques wherever possible.

- Ventilation: Ensure proper ventilation during and after installation to allow any chemical emissions from the panels to dissipate.

- Safety: Always use personal protective equipment (PPE) when cutting or handling panels, as materials can be irritant or hazardous.

By following these detailed preparation and installation steps and tips, installers can ensure that PUF panels, regardless of panel thickness or specific application, perform optimally. Proper installation not only maximizes the energy efficiency benefits of PUF panels but also extends the lifespan of the panels and the structures they are used in.

Cost Considerations for PUF Panel Installation

When selecting PUF panels, understanding the cost dynamics relative to performance and PUF panel thickness is essential. These considerations play a pivotal role in project planning and can significantly impact both immediate expenses and long-term savings.

Cost vs. Performance

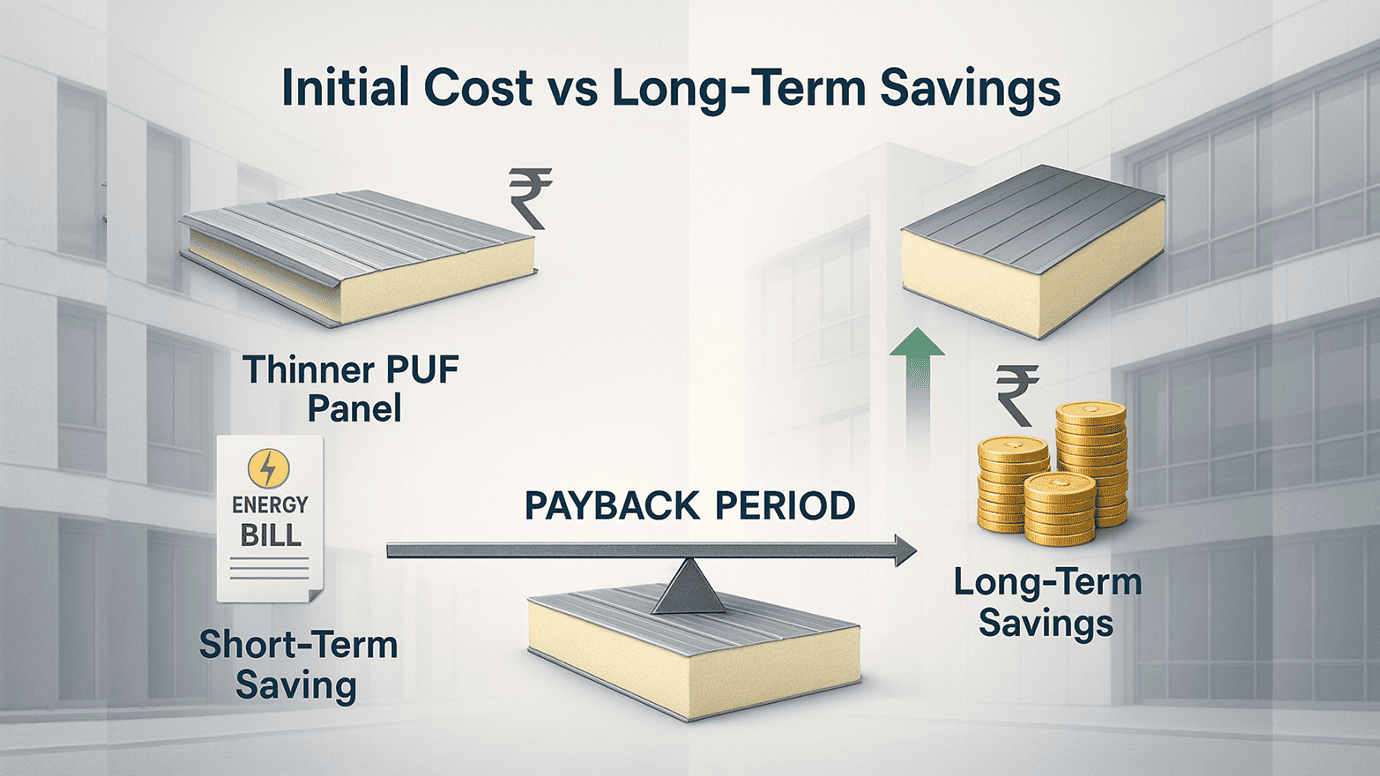

The relationship between PUF panel thickness, performance, and cost is intricate and warrants careful analysis. Generally, as the panel thickness increases, so does the cost. However, thicker panels also provide better insulation, which can be a critical factor in decreasing operational costs in the building’s lifecycle.

- Analysing Trade-offs: Choosing the right panel thickness involves weighing initial investment against potential savings. For instance, while a higher roof panel thickness might increase upfront costs, it could drastically reduce heat loss and energy consumption, especially in colder regions. Similarly, a sufficient cold room panel thickness is crucial in settings like food storage or pharmaceuticals, where precise temperature control is necessary for product integrity and compliance with health regulations.

- Performance Metrics: It's crucial to consider performance metrics such as R-value and thermal conductivity when selecting PUF panels. A panel with a higher R-value, though more costly, will perform better in terms of insulation. The decision should align with the particular needs of the project, whether it is a wall panel thickness in mm for a residential building or an industrial application requiring robust insulation.

Long-term Savings

Investing in the right PUF panel can lead to substantial long-term benefits:

- Energy Savings: Properly insulated buildings require less energy for heating and cooling, which can cause significant cost reductions over the building's life. The energy savings realized from a slightly more expensive, thicker panel often offset the initial higher cost within a few years.

- Durability and Maintenance: Thicker PUF panels typically offer better durability and can withstand harsh environmental conditions, leading to reduced maintenance and repair costs. This is particularly relevant for roof panels exposed to the elements and for cold room panels that must maintain their structural integrity under constant low temperatures.

- Regulatory Incentives: In many regions, investing in energy-efficient materials like high-quality PUF panels can qualify building projects for tax credits, rebates, or other incentives, further offsetting the initial costs.

The decision on PUF panel thickness should be based on a comprehensive cost-benefit analysis, considering both short-term financial outlays and long-term economic and environmental benefits. By selecting the optimal panel thickness, property owners and builders can ensure that their investments are both cost-effective and sustainable, leading to a greener, more economical future. To more about cost of PUF Panels, you can read our blog on PUF Panel Prices.

FAQs

A. For residential applications, a wall panel thickness of 50-100 mm is typically recommended to ensure efficient thermal insulation and energy cost reduction.

A. The roof panel thickness plays a crucial role in energy efficiency, with thicker panels (around 100-150 mm) providing better insulation and thus reducing energy costs in commercial settings.

A. Yes, the panel thickness significantly impacts the load bearing capacity, with thicker panels providing greater structural support and durability.

A. For cold storages, a cold room panel thickness of 150-200 mm is advisable to maintain the necessary low temperatures efficiently.

A. PUF panels should be carefully transported, stored flat away from moisture, and lifted correctly to avoid damage, keeping in mind the specific panel thickness.

A. Factors to consider include the building’s exposure to elements, internal temperature requirements, and load-bearing needs, with roof panel thickness generally being higher to cope with these demands.

A. Yes, climate factors and environmental regulations can dictate the necessary PUF panel thickness to ensure compliance and efficiency in specific regions.

A. While it’s possible, it’s often beneficial to choose a greater roof panel thickness compared to walls to handle additional environmental loads and provide better overhead insulation.

Conclusion

Selecting the appropriate PUF panel thickness is more than a technical decision—it’s a strategic choice that influences the efficiency, sustainability, and cost-effectiveness of a building project. Throughout this discussion, we’ve highlighted the critical role that PUF panel thickness plays in optimizing the performance of various types of constructions, from residential and commercial buildings to industrial facilities and specialized applications.

The importance of choosing the right panel thickness cannot be overstated. For residential buildings, an adequate wall panel thickness in mm and roof panel thickness ensure comfortable living conditions and energy efficiency. In commercial spaces, especially in large buildings or those requiring controlled environments like warehouses and cold storages, the cold room panel thickness is crucial for maintaining proper temperature regulation and energy conservation.

In industrial settings, the demands are even greater, with factors such as extreme temperatures or exposure to harsh conditions dictating the need for a robust PUF panel thickness. These panels not only need to insulate but also to protect, making the choice of thickness a key factor in safeguarding both the structure and its contents.

Moreover, the long-term savings associated with the right PUF panel thickness can be substantial. By investing in the correct thickness, building owners benefit from lower utility costs, fewer maintenance issues, and overall enhanced durability of the structure. This investment also aligns with environmental objectives by reducing the building’s carbon footprint, showcasing the dual benefits of economic and ecological sustainability.

In summary, whether you are determining the cold room panel thickness for a storage facility, selecting the roof panel thickness for a new commercial development, or specifying the wall panel thickness for a residential project, the right PUF panel thickness is key to achieving your goals. It ensures that each building is capable of meeting the specific demands of its environment and usage, translating into benefits that extend far beyond the initial construction phase.

To know more about PUF Panels, go to our PUF Panels Page.